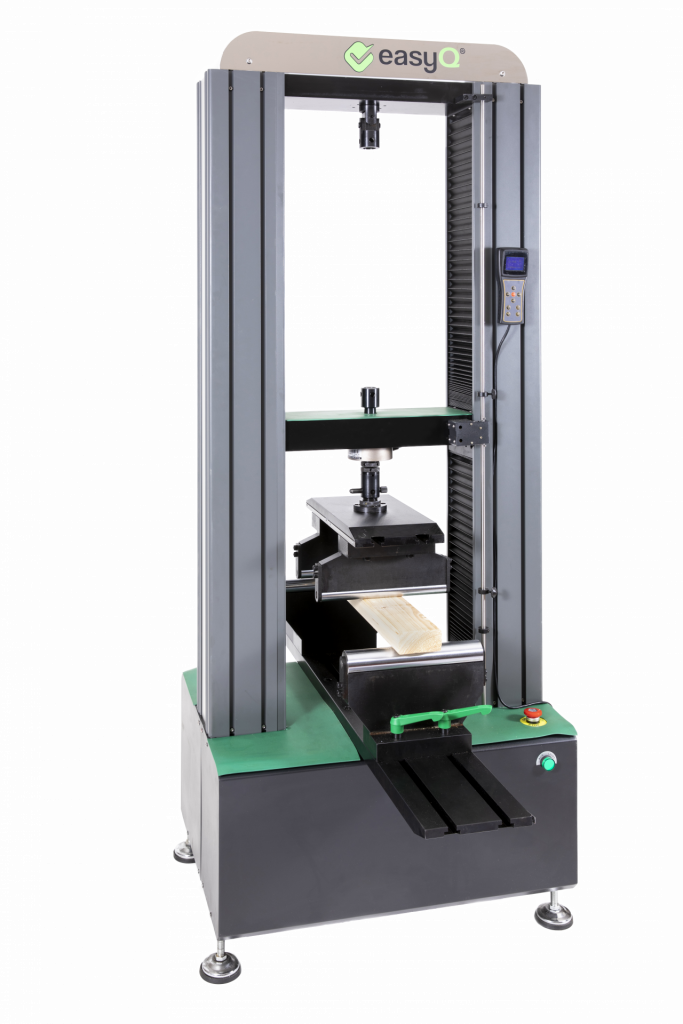

Bending / shear / tensile test

- Gewicht: ab 500kg

- Tiefe: 205cm

- Breite: 308cm

- Höhe: 220cm

- Anschlüsse Werkseitig: Kaltwasser, 3-Phasen 220V

- Anschlüsse Kundenseitig:

- CE Konformität

- Material: Aluminium, Edelstahl

- Heizleistung: 9KW

Product Highlights

- Maximum drying volume for large plants

- Separate chamber control optional

- Fully automated test cycle

- Measured value diagrams and data logging

- Boiler level monitoring

- Temperature & Humidity

- Air speed infinitely variable

- Extremely quiet and energy saving

- Remote diagnosis via Internet

- - Testing according to EN 14080 / 302 / 16351, JAS 235, ASTM D 2559, AS/NZS 1428, AITC T110 and freely programmable

- Extremely short teach-in times

Function

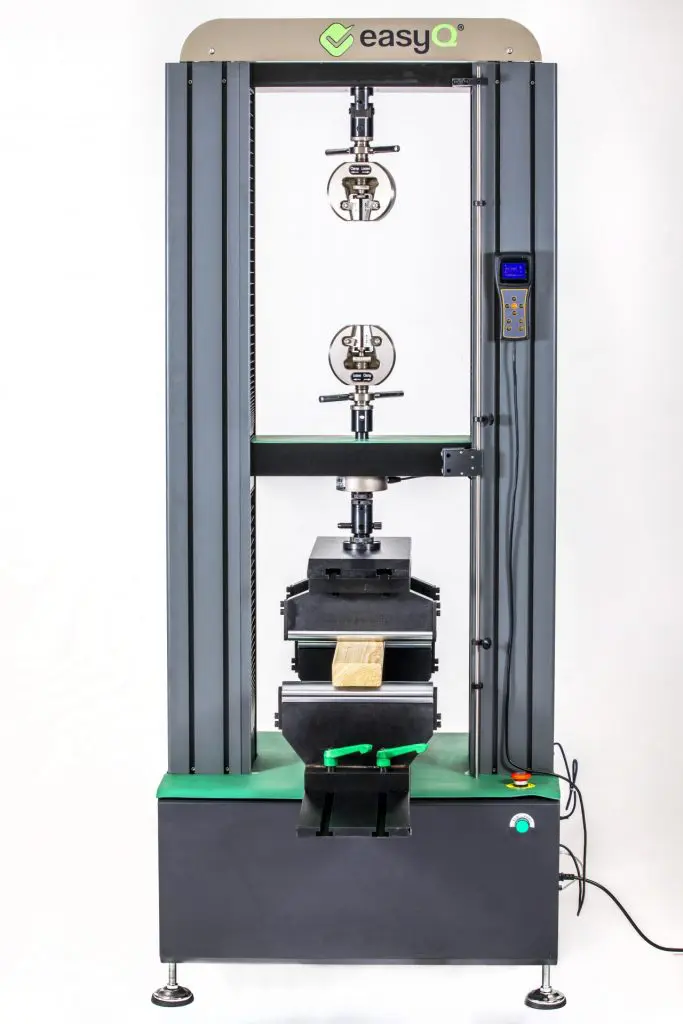

3-point / 4-point bending testing machine according to EN14080 / EN 408 for structural timber products

with special focus on finger joints. Other test standards on request.

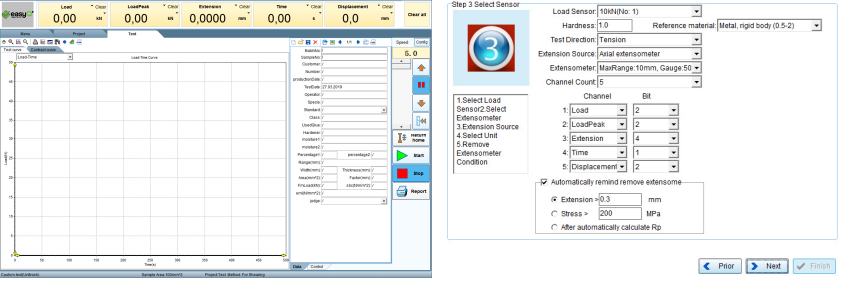

Support and load distance manually adjustable. The software provides

the values according to the standard.

Electromechanical load device with servo drive and ball screw bearing.

A load cell measures the actual load according to EN408 with an accuracy of

< +/-1%.

Fully automatic test sequence by mouse click by means of software as well as manual control box

on the machine. A PC is not included as standard but optionally available.

Load speed continuously adjustable on PC.

Extensive programming possibilities in the software, e.g. time-, travel- or

force-controlled test sequence.

Display and recording of the load diagram in the software.

Export (Excel) and reporting functions.

Incl. software for controlling the machine and documentation of measured values and test results as well as automatic storage. No separate PC is included. If our test stand eQLab 4.0 is also ordered, the software can run on this PC.

For this purpose, only the test stand must be located near the bending test machine. Also any existing Windows PC with Windows 7-10 and USB interface can be used.

can be used.

Operating languages: German, English

OPTIONS

The UTM -UniversalTestMachine- is of modular design. Various testing and measuring devices can be added to the basic machine (closed frame construction) and are docked onto the base frame or cross beam. Customer-specific fixtures and clamping devices can also be added to the

clamping device can be added. Here is an excerpt of the fixtures relevant for timber construction:

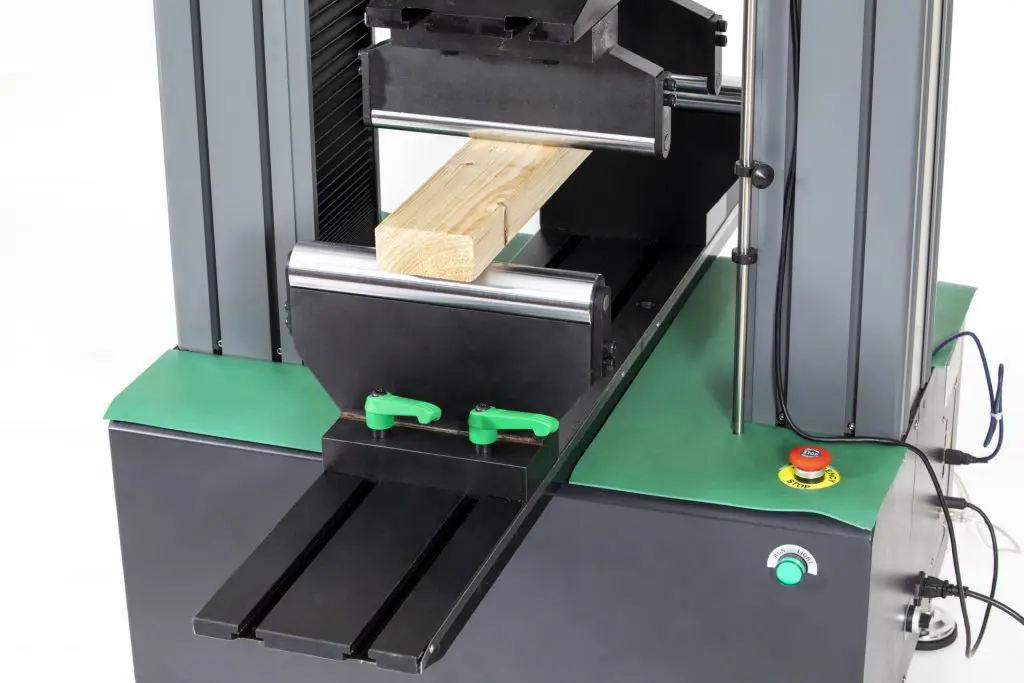

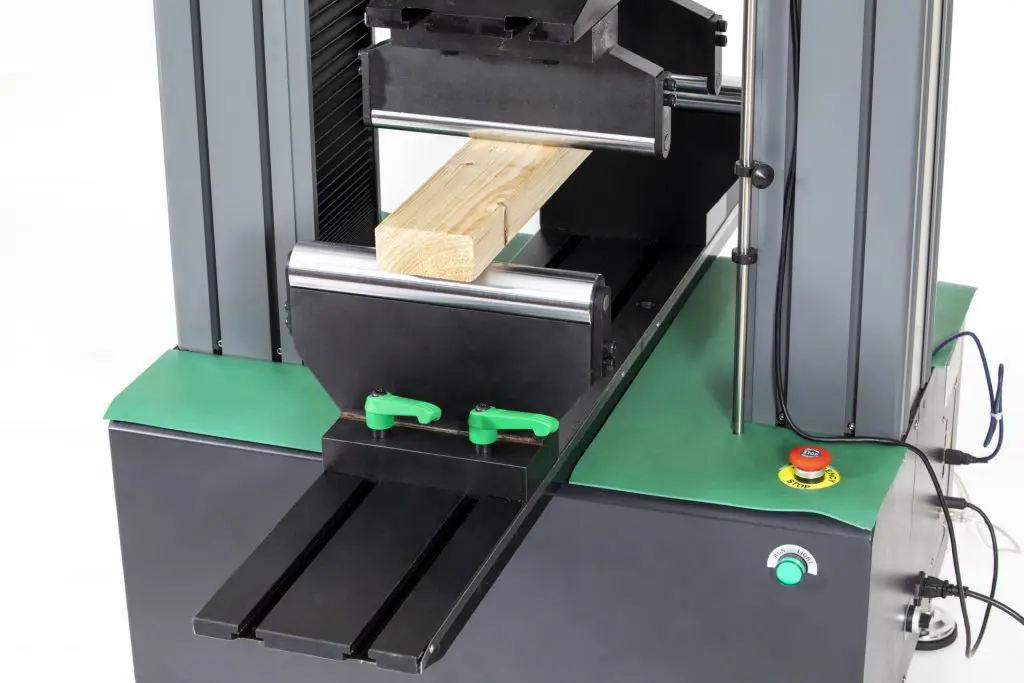

3-point/ 4-point bend test fixture:

As a rule, this is always included with the machine. See above. However, it is

machine is also available without a bending test device, e.g. if the machine is to be used

it is to be used as a pure shear testing machine.

Standard bend test fixtures are 1200 / 400 mm (UTM50), 2100/700 mm

(UTM100) as well as 3000/1000 mm (UTM200).

Other versions are available on request.

Shear test device:

Shear fixture for determining the shear strength

according to EN14080. Shear area 50x50mm.

Other shear areas or other standards on request.

The fixture has a clamping device

and a bushing for hooking into the mounting mandrel of the

mounting mandrel of the testing machine.

Incl. software extension.

Bending test

Clamping device for determining the rolling shear strength of cross laminated timber according to

EN16351.

For insertion into bending testing machine

Max. Specimen size: 100 x 300 mm. Thickness adjustable up to max. 300 mm.

Incl. software extension.

Roller shear test device:

Clamping device for determining the rolling shear strength of cross laminated timber according to EN16351. For insertion into bending testing machine Max. Specimen size: 100 x 300 mm. Thickness adjustable up to max. 300 mm. Incl. software extension.

UTM 50

Maximum test load = 50 kN

Bend test fixture with 1200 mm support distance and 400 mm load distance.

Other distances on request.

UTM 100

Maximum test load = 100 kN

Bend test fixture with 2100 mm support distance and 700 mm load distance.

Other distances on request.

UTM 200

Maximum test load = 200 kN

Bend test fixture with 3000 mm support distance and 1000 mm load distance.

Other distances on request.